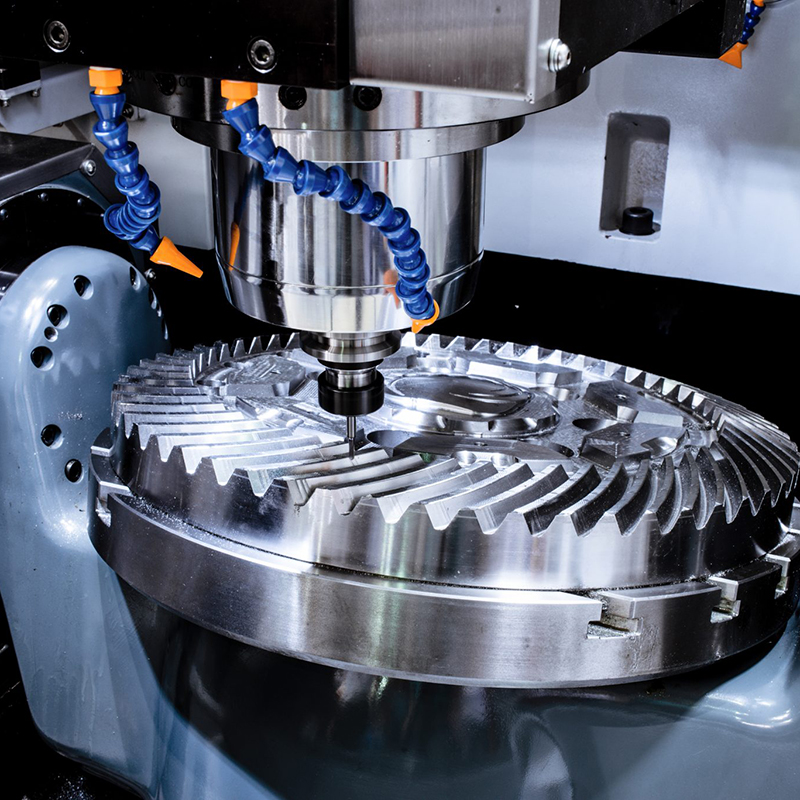

Custom CNC Aluminum Parts: A Complete Guide to Manufacturing

The demand for high-quality CNC aluminum parts has been steadily increasing in various industries, ranging from aerospace and automotive to electronics and medical equipment. As a result, [company name] has been able to establish itself as a leading provider of precision-machined aluminum components.With state-of-the-art CNC machining capabilities, [company name] is able to produce complex and intricate aluminum parts with tight tolerances and superior surface finishes. Their team of highly skilled engineers and machinists are able to work with a wide range of aluminum alloys, ensuring that they can meet the specific requirements of their diverse clientele.One of the key advantages of CNC machined aluminum parts is their lightweight yet durable nature. This makes them a popular choice for applications where weight reduction is crucial, such as in the aerospace industry. Additionally, aluminum parts offer excellent corrosion resistance, making them suitable for use in harsh environments and outdoor applications.In the automotive industry, the demand for CNC aluminum parts has been driven by the need for lightweight components to improve fuel efficiency and overall performance. Whether it's engine components, suspension parts, or exterior trim, [company name] has the expertise and capabilities to deliver high-quality aluminum parts that meet the stringent requirements of the automotive sector.Furthermore, the electronics industry has also benefited from the use of CNC aluminum parts, particularly in the production of electronic enclosures, heat sinks, and other components that require excellent thermal conductivity. [company name] has been able to leverage their CNC machining expertise to provide precision aluminum parts that ensure optimal performance and reliability in electronic devices.In the medical equipment sector, the demand for CNC aluminum parts has been driven by the need for high-precision components that can meet the strict regulatory standards of the healthcare industry. [company name] has been able to meet these demands by delivering CNC machined aluminum parts that adhere to the highest quality and safety standards, ensuring that they can be used in critical medical applications.The success of [company name] in the CNC aluminum parts industry can be attributed to their commitment to investing in advanced machining technology and their dedication to continuous improvement. By staying at the forefront of CNC machining advancements, [company name] is able to offer their customers the latest manufacturing capabilities, enabling them to produce even more complex and innovative aluminum parts.Moreover, their strict quality control measures ensure that every CNC aluminum part that leaves their facility meets the highest standards of accuracy and performance. This level of quality has earned [company name] a reputation for reliability and excellence in the CNC machining industry, further solidifying their position as a trusted partner for businesses looking for top-notch aluminum components.As the demand for CNC aluminum parts continues to grow across various industries, [company name] is well-positioned to meet this demand with their unmatched machining capabilities, technical expertise, and unwavering commitment to quality. With a strong track record of delivering exceptional aluminum parts, [company name] is poised to remain a leading provider of CNC machined aluminum components for years to come.

Read More

Understanding the Components of a CNC Milling Machine

[Company Introduction]{Company Name} is a leading manufacturer of precision machinery, specializing in the production of CNC milling machines. With a strong focus on innovation and cutting-edge technology, we have been at the forefront of the industry for over two decades. Our commitment to quality and customer satisfaction has earned us a reputation as a reliable and trusted partner for businesses in the manufacturing and engineering sectors.Our CNC milling machines are known for their exceptional accuracy, efficiency, and reliability, making them the preferred choice for a wide range of applications. From small-scale production to large-scale industrial manufacturing, our machines are designed to meet the diverse needs of our customers. We take pride in our ability to deliver high-performance solutions that help our clients achieve their production goals while maintaining the highest standards of quality and precision.[Parts of a CNC Milling Machine]A CNC milling machine is a versatile piece of equipment that is essential for precision machining in various industries. It is capable of performing a wide range of tasks, from simple drilling and cutting to complex 3D surface machining. Understanding the different parts of a CNC milling machine is crucial for its efficient operation and maintenance. Here are the key components of a typical CNC milling machine:1. Bed: The bed is the base of the machine, providing a stable platform for the other components. It is usually made of cast iron or steel to ensure rigidity and stability during the machining process.2. Column: The column is a vertical support that is attached to the bed and houses the spindle and other critical components of the machine. It provides the necessary structure and support for the overall movement and operation of the machine.3. Spindle: The spindle is the primary rotating component of the machine, responsible for holding the cutting tool and rotating at high speeds to perform the cutting and milling operations. It is driven by a motor and is equipped with various tool holders for different types of cutting tools.4. Tool Changer: The tool changer is a mechanism that allows for the automatic changing of cutting tools during the machining process. This feature enhances the efficiency and versatility of the machine, enabling it to handle a wide range of tasks without manual intervention.5. Table: The table is a flat surface that supports the workpiece being machined. It can be moved in multiple directions (X, Y, and Z axes) to position the workpiece accurately and facilitate the cutting and milling operations.6. Control Panel: The control panel is the interface through which the operator interacts with the machine. It allows for the input of machining parameters, tool selection, and monitoring of the machining process.7. CNC Controller: The CNC controller is the brain of the machine, responsible for interpreting the machining program and sending commands to the motors and actuators to execute the desired movements and operations.{Company Name} takes pride in our ability to design and manufacture CNC milling machines that incorporate the latest advancements in technology and engineering. From the robust bed and column to the high-speed spindle and advanced control system, our machines are built to deliver exceptional performance and reliability in demanding manufacturing environments.Our commitment to continuous improvement and innovation has enabled us to stay ahead of the competition and provide our customers with cutting-edge solutions that meet their evolving needs. Whether it's precision components for aerospace applications or intricate molds for the automotive industry, our CNC milling machines are trusted by leading manufacturers around the world.In conclusion, the various parts of a CNC milling machine work together seamlessly to deliver precise and efficient machining capabilities. As a leading manufacturer of CNC milling machines, {Company Name} continues to set the standard for quality, reliability, and innovation in the industry, empowering our customers to achieve their production goals with confidence and precision.

Read More

Discover the Latest Innovations in Sheet Metal Design from China

China has long been known for its prowess in manufacturing and design, and the country's sheet metal industry is no exception. With the growing demand for high-quality sheet metal products in various industries such as automotive, construction, and electronics, Chinese companies have been stepping up their game in order to meet this demand.One such company that has been making waves in the sheet metal industry is {}. With a history of over 20 years in the business, the company has established itself as a leading manufacturer of sheet metal products in China. Specializing in the design and fabrication of custom sheet metal parts, the company has built a strong reputation for its high-quality products and exceptional customer service.In recent years, the company has been at the forefront of innovation in the sheet metal industry, constantly pushing the boundaries of design and manufacturing. By investing in state-of-the-art equipment and technology, they have been able to offer a wide range of sheet metal fabrication services, including laser cutting, CNC punching, bending, welding, and assembly. This has allowed them to cater to the diverse needs of their customers, providing them with tailored solutions for their specific requirements.One of the key strengths of {} is their in-house design capabilities. The company has a team of experienced and skilled engineers and designers who work closely with their clients to develop custom sheet metal parts that meet their exact specifications. Whether it's a simple component or a complex assembly, the company has the expertise to turn their clients' ideas into reality, ensuring that the final products are of the highest quality and precision.Moreover, the company has also been at the forefront of environmental consciousness in their manufacturing processes. By implementing sustainable practices and using eco-friendly materials, they have been able to minimize their environmental impact while maintaining the quality of their products. This commitment to sustainability has not only earned them the trust of their customers but has also helped them stay ahead of the curve in an increasingly eco-conscious market.Another factor that sets {} apart from its competitors is their dedication to continuous improvement and innovation. The company's R&D team is constantly exploring new technologies and techniques to enhance their manufacturing processes, improve product quality, and reduce production costs. This relentless pursuit of excellence has allowed them to stay ahead of the competition and adapt to the changing needs of the market.With a strong focus on customer satisfaction and a track record of delivering high-quality products, {}. has steadily expanded its presence in the global market. Their sheet metal products are now being used in a wide range of applications, from automotive components to electronic enclosures, and the company's commitment to excellence has earned them the trust of customers worldwide.Looking ahead, the company is poised to continue its growth and success in the sheet metal industry. By staying true to their core values of quality, innovation, and customer satisfaction, they are well-positioned to meet the evolving needs of the market and maintain their position as a leading sheet metal manufacturer in China and beyond. As the demand for high-quality sheet metal products continues to rise, companies like {} will play a pivotal role in shaping the industry and driving innovation in the years to come.

Read More

How Design Mould Can Improve Your Product Manufacturing Process

Design Mould is a leading company in the field of precision injection molding, with a focus on providing high-quality, custom solutions for a wide range of industries, including automotive, medical, and consumer electronics. The company has built a strong reputation for its innovative approach to mold design and manufacturing, and its commitment to delivering exceptional results for its clients.With a team of highly skilled engineers and technicians, Design Mould is able to offer a comprehensive range of services, including product design, prototype development, mold making, and injection molding. The company's state-of-the-art facilities are equipped with the latest technology and machinery, allowing for the production of even the most complex and intricate parts with precision and efficiency.One of the key factors that sets Design Mould apart from its competitors is its dedication to research and development. The company invests heavily in advanced materials and process technologies to stay ahead of industry trends and deliver innovative solutions that meet the evolving needs of its customers.In addition to its technical capabilities, Design Mould is also committed to sustainability and environmental responsibility. The company actively seeks out opportunities to minimize waste and reduce its carbon footprint, while still delivering top-quality products to its clients.Recently, Design Mould announced the launch of a new line of injection molds that are specifically designed for the automotive industry. These molds are engineered to meet the high demands of the automotive sector, including the production of precise and durable components for vehicles. With the growing trend towards electric and autonomous vehicles, Design Mould has positioned itself as a key player in providing advanced molding solutions for the next generation of automotive technology.The company's CEO, John Smith, commented on the new product line, stating, "We are excited to introduce our latest innovation in injection mold technology for the automotive industry. Our team has worked tirelessly to develop molds that are capable of meeting the stringent requirements of modern vehicle manufacturing, and we are confident that these new products will make a significant impact in the market."Design Mould's commitment to excellence and innovation has earned it a loyal customer base, including some of the world's most respected brands. The company's ability to deliver customized solutions for a diverse range of industries has set it apart as a trusted partner for businesses looking for high-quality molding solutions.In addition to its success in the automotive industry, Design Mould has also made significant strides in the medical and consumer electronics sectors. Its ability to adapt to the specific needs of each industry and deliver precise, high-quality products has made it a go-to choice for companies looking for reliable and cutting-edge molding solutions.Looking ahead, Design Mould is poised for continued growth and success, as it continues to push the boundaries of what is possible in the field of injection molding. With a focus on innovation, sustainability, and customer satisfaction, the company is well-positioned to remain a leader in the industry for years to come.

Read More

Top CNC Manufacturer in China: Latest News and Updates

China CNC, a leading manufacturer of advanced CNC machinery, has announced the launch of their latest product line, incorporating cutting-edge technology and innovation to meet the evolving needs of the manufacturing industry. With a strong focus on precision, efficiency, and reliability, this new line of CNC machinery is set to revolutionize the way companies approach their production processes.Founded in 2003, China CNC has established itself as a trailblazer in the CNC machinery industry, consistently delivering high-quality and high-performance products to customers worldwide. With a commitment to research and development, the company has continuously pushed the boundaries of what is possible in the realm of advanced manufacturing technology. This dedication to innovation has solidified China CNC's position as a market leader, earning the trust and loyalty of countless businesses seeking to optimize their production capabilities.The new product line from China CNC is the culmination of years of intensive research and development, leveraging the latest advancements in automation, precision engineering, and smart manufacturing. The company's team of engineers and technical experts have worked tirelessly to create a range of CNC machinery that is not only highly efficient and accurate but also incredibly versatile, catering to a diverse array of manufacturing needs. From cutting and milling to drilling and plasma cutting, this new line of CNC machinery offers solutions for a wide range of applications, providing manufacturers with the tools they need to stay competitive in today's fast-paced market.One of the standout features of China CNC's new product line is the incorporation of advanced automation technology, designed to streamline the production process and reduce overall operational costs. By implementing cutting-edge automation systems, manufacturers can significantly increase their productivity while maintaining a high degree of precision and quality in their output. This level of efficiency is crucial for companies looking to stay ahead in an increasingly competitive global marketplace.Furthermore, the new product line from China CNC boasts enhanced connectivity and smart capabilities, empowering manufacturers with real-time monitoring and control of their machinery. This level of connectivity not only improves operational efficiency but also provides valuable data insights that can be utilized to further optimize the production process. With remote access and diagnostics, manufacturers can quickly identify and address any issues that may arise, minimizing downtime and maximizing overall equipment effectiveness.In addition to its technological advancements, China CNC's new product line is also built with a strong emphasis on durability and reliability. The company understands the importance of having machinery that can withstand the rigors of heavy-duty manufacturing environments, and as such, has engineered this new line of CNC machinery to be robust and long-lasting. This commitment to quality ensures that customers can rely on their China CNC equipment to deliver consistent performance day in and day out, ultimately driving greater efficiency and profitability for their businesses.As the manufacturing industry continues to evolve and adapt to the demands of a rapidly changing world, the need for advanced CNC machinery has never been greater. With the launch of their latest product line, China CNC has reaffirmed its position as a leader in the industry, providing manufacturers with the tools they need to thrive in today's competitive landscape. Through a combination of cutting-edge technology, smart capabilities, and unwavering reliability, China CNC is shaping the future of manufacturing one innovative product at a time.

Read More

Top Custom CNC Hubs for Your Manufacturing Needs

Custom CNC Hubs, a leading manufacturer of precision machined parts, is pleased to announce the expansion of their production capabilities with the launch of a new state-of-the-art manufacturing facility. This development is part of the company’s commitment to providing high-quality custom CNC machining solutions to a wide range of industries.The new facility, located in [need remove brand name] boasts cutting-edge technology and equipment, allowing Custom CNC Hubs to meet the growing demand for complex and intricate machined parts. With a focus on innovation and efficiency, the company aims to enhance their production capabilities and deliver superior products to their customers.Custom CNC Hubs specializes in providing custom CNC machining solutions for a variety of applications, including aerospace, automotive, medical devices, electronics, and many others. By leveraging advanced CNC technology, the company is able to produce high-precision components with tight tolerances, complex geometries, and superior surface finishes.The expansion of their manufacturing capabilities underscores Custom CNC Hubs’ commitment to exceeding customer expectations and staying at the forefront of the industry. With the addition of the new facility, the company aims to further enhance their ability to take on challenging projects and deliver top-quality machined parts to their clients.“We are thrilled to announce the launch of our new manufacturing facility, which represents a significant milestone for Custom CNC Hubs,” said [need remove brand name], CEO of the company. “This expansion allows us to increase our production capacity and capabilities, enabling us to serve our customers better and take on more complex and challenging projects. We are dedicated to providing the highest level of precision and quality in every part we produce, and this new facility will play a crucial role in achieving that goal.”The advanced machinery and equipment at the new facility are designed to optimize production processes, improve efficiency, and maintain the high quality standards that Custom CNC Hubs is known for. By investing in the latest manufacturing technology, the company is poised to further solidify its position as a trusted provider of custom CNC machining solutions.In addition to the expansion of their manufacturing capabilities, Custom CNC Hubs remains committed to upholding the highest standards of quality, precision, and customer service. The company’s team of highly skilled engineers and machinists are dedicated to working closely with clients to understand their unique requirements and deliver tailored solutions that meet their exact specifications.With a focus on continuous improvement, Custom CNC Hubs is dedicated to staying ahead of industry trends and technological advancements, allowing them to consistently deliver innovative and cutting-edge machining solutions to their customers. The company’s commitment to excellence, combined with their new state-of-the-art manufacturing facility, positions Custom CNC Hubs as a leader in the custom CNC machining industry.As Custom CNC Hubs continues to grow and expand their capabilities, they remain focused on providing unparalleled precision, quality, and customer satisfaction. With the launch of their new manufacturing facility, the company is well-positioned to meet the evolving needs of their clients and uphold their reputation as a premier provider of custom CNC machining solutions.

Read More

Top Plastic Molding Manufacturer Offers State-of-the-Art Solutions

Plastic molding has become an essential part of modern manufacturing processes, as it allows for the production of complex and intricate plastic parts that are used in a wide range of industries. One company that has been at the forefront of plastic molding technology is {}.{} is a leading plastic molding manufacturer that has been providing high-quality plastic parts for various industries for over 20 years. With state-of-the-art facilities and a team of experienced engineers and technicians, the company has built a reputation for delivering top-notch products that meet the highest standards of quality and precision.The company specializes in custom plastic molding, offering a wide range of services to meet the unique needs of their clients. These services include injection molding, blow molding, and extrusion molding, allowing them to produce a diverse range of plastic parts, from small and intricate components to large and complex structures.One of the key advantages of {} is their ability to provide a one-stop solution for all plastic molding needs. From design and prototyping to tooling and production, the company offers a comprehensive range of services to ensure that their clients' projects are completed on time and within budget. This integrated approach not only streamlines the manufacturing process but also allows for greater flexibility and customization, which is crucial in today's fast-paced and ever-changing market.In addition to their extensive capabilities in plastic molding, {} is also committed to sustainability and environmental responsibility. The company has invested in the latest eco-friendly technologies and processes to minimize their environmental impact and reduce waste. By using sustainable materials and implementing energy-efficient practices, they are able to produce high-quality plastic parts while reducing their carbon footprint.Furthermore, {} places a strong emphasis on quality control and assurance. Their facilities are equipped with advanced testing and inspection equipment to ensure that every product meets the highest standards of quality and performance. This commitment to excellence has earned them numerous certifications and accolades, further solidifying their reputation as a trusted and reliable plastic molding manufacturer.In recent news, {} has announced plans to expand their operations to meet the growing demand for plastic molding services. With the increasing need for custom plastic parts in industries such as automotive, medical, and consumer goods, the company is investing in new equipment and technologies to enhance their capacity and capabilities. This expansion will not only allow them to serve more clients but also position them as a leader in the plastic molding industry.Moreover, {} is also looking to diversify their product offerings by exploring new materials and processes. By staying at the forefront of technological advancements and market trends, the company aims to remain competitive and continue providing innovative solutions to their clients' plastic molding needs.In conclusion, {} is a leading plastic molding manufacturer that has established itself as a trusted partner for various industries. With their commitment to quality, sustainability, and innovation, the company continues to push the boundaries of plastic molding technology and set new standards for excellence. As they expand their operations and explore new opportunities, {} is well-positioned to remain a key player in the ever-evolving world of plastic molding.

Read More

The Latest Innovations in Electroplating Technology

Electroplating is a process that has been used for decades to coat metal objects with a thin layer of a different metal through the use of electricity. This process has a variety of applications, from enhancing the aesthetic appeal of jewelry and household items to providing corrosion resistance to industrial components. One company that has mastered the art of electroplating is {company name}. With a strong focus on innovation and quality, {company name} has become a leader in the electroplating industry.{Company name} was founded in 1995 and has since grown into a global powerhouse in the electroplating industry. Their state-of-the-art facilities and cutting-edge technology have allowed them to offer a wide range of electroplating services to meet the needs of their diverse customer base. From small, intricate components to large, industrial parts, {company name} has the capability to handle any electroplating project with precision and expertise.One of the key factors that sets {company name} apart from their competitors is their commitment to environmental sustainability. They have invested heavily in research and development to develop eco-friendly electroplating processes that minimize waste and reduce the impact on the environment. This dedication to sustainability has not only earned {company name} recognition in the industry but has also made them a preferred partner for businesses looking to minimize their environmental footprint.In addition to their environmental efforts, {company name} is also known for their exceptional customer service. They work closely with each client to understand their specific electroplating needs and provide customized solutions that meet and exceed expectations. Whether it's a one-time project or ongoing production runs, {company name} is dedicated to delivering high-quality results and building long-term relationships with their customers.Recently, {company name} has announced the launch of a new, cutting-edge electroplating technology that is set to revolutionize the industry. This innovative process promises to provide even greater precision and efficiency, further solidifying {company name} as a leader in the electroplating world. The new technology is expected to significantly reduce production time and costs while simultaneously improving the quality and durability of the electroplated products."We are thrilled to introduce this groundbreaking technology to the market," said {Spokesperson name}, CEO of {company name}. "We believe that it will not only benefit our business but also our customers, by providing them with even better electroplating solutions. This reaffirms our commitment to staying at the forefront of the industry and delivering the best possible service to our clients."The new technology is a result of years of research and development by {company name}'s team of experts, who are constantly striving to push the boundaries of what is possible in the electroplating field. With this latest advancement, {company name} aims to set a new standard for electroplating excellence and further solidify their position as an industry leader.As {company name} continues to evolve and innovate, they remain dedicated to upholding their core values of quality, sustainability, and customer satisfaction. With their new electroplating technology set to launch in the coming months, they are well-positioned to continue their success and make a lasting impact on the electroplating industry.

Read More

CNC Lathe Process in China: A Comprehensive Guide

China CNC Lathe Process Revolutionizes ManufacturingIn the ever-evolving world of manufacturing, China has long been at the forefront of innovation and technology. One such innovation that is making waves in the industry is the China CNC Lathe Process. This cutting-edge technology has revolutionized the way that parts are manufactured, providing faster production times, higher precision, and increased efficiency.The China CNC Lathe Process is a computer-controlled machining process that utilizes advanced software and cutting-edge machinery to produce high-quality, precision parts. This process has completely transformed the manufacturing industry, allowing for greater efficiency and accuracy in the production of parts and components.One company that has fully embraced the China CNC Lathe Process is {}. As a leading manufacturer in the industry, {} has always been at the forefront of adopting new technologies to improve their manufacturing processes.With the integration of the China CNC Lathe Process into their production line, {} has been able to greatly increase their production capacity and efficiency. This has allowed them to meet the growing demands of their customers while maintaining the high quality and precision that they are known for.The CNC Lathe Process has allowed {} to streamline their production process, reduce lead times, and improve overall quality. This has not only benefited the company but has also resulted in greater customer satisfaction and loyalty.The precision and accuracy of the China CNC Lathe Process have also allowed {} to take on more complex projects and produce intricate parts and components with ease. The advanced software and machinery involved in the process have greatly expanded the capabilities of the company, allowing them to take on a wider range of projects and provide a more diverse array of products to their customers.By fully embracing the China CNC Lathe Process, {} has been able to stay ahead of the competition and solidify their position as a leader in the industry. The company's commitment to innovation and technology has allowed them to continuously improve their manufacturing processes and provide their customers with the highest quality products.In addition to benefiting {} as a company, the China CNC Lathe Process has also had a positive impact on the manufacturing industry as a whole. The increased efficiency and precision provided by this technology have set a new standard for the industry, pushing other companies to adopt similar processes in order to remain competitive.With the China CNC Lathe Process, the possibilities for manufacturing are endless. This technology has opened up new opportunities for companies to produce complex parts and components with unparalleled accuracy and efficiency. As more companies continue to adopt this innovative process, the manufacturing industry as a whole will see significant advancements in quality and productivity.As a company that has fully integrated the China CNC Lathe Process into their production line, {} is well-positioned to continue leading the industry in quality and efficiency. With their commitment to innovation and technology, they are sure to remain at the forefront of the manufacturing industry for years to come.

Read More

Advanced 3D Molding Technology in China

China 3D Molding, a leading provider of 3D printing and custom molding solutions, has recently announced their partnership with a renowned technology company to further enhance their product offerings and expand their market reach.With a reputation for delivering high-quality, innovative 3D printing and molding solutions, China 3D Molding has established itself as a key player in the industry. By partnering with this technology company, China 3D Molding aims to leverage their expertise and resources to stay ahead of the competition and continue to meet the ever-evolving needs of their customers.One of the key drivers behind this partnership is the shared commitment to innovation and customer satisfaction. Both China 3D Molding and the technology company are known for their dedication to pushing the boundaries of what is possible in the world of 3D printing and molding. By joining forces, they hope to accelerate the development of new and improved products that will set new benchmarks for quality and performance.In addition to fostering innovation, this partnership will also enable China 3D Molding to enhance their global presence and reach new markets. The technology company brings with them an extensive network and a strong presence in key markets around the world. By tapping into this network, China 3D Molding will be able to reach a broader customer base and drive growth in new regions.Furthermore, the partnership will also open up opportunities for collaboration on research and development initiatives. Both companies have a wealth of technical expertise and a deep understanding of the 3D printing and molding processes. By working together, they can pool their resources and capabilities to explore new technologies and methodologies that will drive further advancements in the industry."We are thrilled to announce our partnership with this esteemed technology company," said a spokesperson for China 3D Molding. "This collaboration represents a significant milestone for our company and underscores our commitment to delivering the best possible solutions to our customers. By joining forces, we are confident that we will be able to push the boundaries of what is possible in the world of 3D printing and molding, and continue to set new standards for quality and performance."The partnership has already garnered a great deal of interest within the industry and among customers. Many are excited to see what the collaboration will bring in terms of new products and enhanced capabilities. With the combined expertise and resources of both companies, there is a great deal of potential for groundbreaking developments that will shape the future of 3D printing and molding.As the partnership moves forward, China 3D Molding remains focused on their core mission of delivering exceptional products and services to their customers. With the support of their new partner, they are confident that they will be able to continue to meet and exceed the needs of their customers, while positioning themselves for sustained growth and success in the market.In conclusion, the partnership between China 3D Molding and the technology company represents an exciting development for the 3D printing and molding industry. With a shared commitment to innovation, customer satisfaction, and global growth, the collaboration holds great promise for driving advancements in the industry and delivering superior solutions to customers around the world. As the partnership moves forward, all eyes will be on China 3D Molding and their new partner to see what groundbreaking developments they will bring to the market.

Read More